May 26, 2023

What’s the Difference Between Steel and Alloy Wheels?

Thinking of changing your wheels for aesthetic reasons? Before shopping, you should know that wheels do more than make your ride look cooler; they also link your vehicle to the road, which is why they affect the following:

• Safety

Wheels make precise steering possible, and if any of them are defective, you won't have complete control over your vehicle. This may result in an accident.

• Handling

Larger wheels need larger tyres, which have a wider contact patch against the ground. This delivers better grip and handling, giving you better traction and shorter braking distances.

• Fuel Efficiency

The bigger and heavier the wheel, the more effort and fuel it requires to move your vehicle forward.

So, which wheel material is better for you—steel or alloy? This article discusses the merits, drawbacks, and driving habits most suitable for each.

Steel and Alloy Wheels—Which Is Better?

There are two basic wheel types in the market—alloy (also called aluminium) and steel. Most of today's wheels are alloy because it’s more affordable and comes in various designs. Meanwhile, heavier and bigger vehicles use steel wheels because of their durability. Let's jump into the pros and cons of each wheel.

What Are Alloy Wheels?

Alloy wheels are a mix of non-metals and metals typically dominated by nickel and magnesium. Aluminium, their base material, is ideal for wheels because it's lightweight yet durable. Most of today's vehicles usually come with OE (original equipment) alloy wheels. Read below for its pros and cons to determine if it's the right wheel for you.

Advantages of Alloy Wheels

• Visual Appeal

Alloy wheels are perfect for style-seekers because they come in various designs and finishes. Borne from motorsport technology, these wheels are built for a sportier look and performance than their steel versions.

• Better Performance

The main reason for this wheel's high performance is its reduced weight. In motorsport, every pound counts to make your ride lighter and faster. As a result, alloy wheels contribute to shorter braking distances, quicker acceleration, and better manoeuvrability.

• Higher Fuel Economy

Because alloy wheels are lighter than steel wheels, your engine doesn't have to consume as much fuel while moving. They are also gentler on your vehicle's suspension system, which is vital for steering control and comfort.

• Better Heat Conduction

Alloy wheels conduct heat faster, which boosts braking ability. Stopping the car becomes safer and easier on long trips and rugged roads, and you don't have to worry about damaging the brakes. These wheels also dissipate heat more effectively, which extends wheel life.

• Resistance to Rust

Aluminium is known for its resistance to rust and dust, which makes for easier cleaning and a longer shine. However, these wheels can corrode, potentially damaging your wheels, tyres, and transmission system.

Disadvantages of Alloy Wheels

• Not as Durable

This is the main drawback of alloy wheels. Because they are more pliable than steel, they can easily bend or crack during road impacts. But the effect goes beyond cosmetics; driving on compromised wheels is also unsafe.

• More Expensive

Alloy wheels may look good but aren't pocket-friendly due to costlier materials and complicated production techniques. These wheels are made through wheel casting or setting molten aluminium in a mould and forging, wherein pre-cut aluminium is milled and then forged.

• Harder to Repair

Because alloy wheels are more easily damaged, repairing them can get complicated. To tell if they're repairable, check if the bent part is at the same level as the wheel's centre. If the entire wheel has been damaged, then you need to replace it.

• Not for Winter

Alloy wheels are more prone to corrosion (and oxidation). When this happens, tiny bubbles form on the flange or the rim's edge. With oxidised wheels, tyres can lose pressure, causing an unstable ride. However, alloy wheels can now be winter-proofed, which means additional cost.

What are Steel Wheels?

Steel wheels are a combination of iron and carbon. While alloy wheels are about style and functionality, steel wheels are best known for their durability—which is why powerful vehicles like SUVs, trucks, and buses use them.

Advantages of Steel Wheels

• Resistance to Damage

Steel is one of the stronger metals around. Attesting to steel's durability is its use in construction and building projects. Unlike alloy wheels that are moulded or forged, steel wheels are cut on a press and welded, making them especially strong. They can't be cracked or bent easily, making them the perfect option for winter driving.

• Boosted Ride Comfort

Because steel wheels are thicker, they require tyres with a high profile. Tyres with thicker sidewalls have more rubber that acts as shock absorbers, which gives you a more comfortable ride.

• Less Expensive

Because of its straightforward materials and manufacturing process, steel wheels are more affordable than alloy wheels.

• Easier Maintenance & Repair

All you have to do is keep a layer of paint on your steel wheels to ensure they're in good working condition. Though it's hard to bend the wheel, it can still happen. To repair it, your mechanic can use a hammer to put it back into shape.

Disadvantages of Steel Wheels

• Less Aesthetic Choices

"Rough and tough" is the only look steel wheels can pull off. They certainly don't have a sleek styling that is racetrack-compatible. However, their dependability makes up for their utilitarian appearance.

• Limited Sizes

These wheels are available only in sizes of 16 inches and below. Anything bigger than that and the wheels would add too much weight to the vehicle. This wheel type is best compatible with vehicles specifically built for them, so you can't upgrade to steel wheels on a whim.

• Increased Fuel Consumption

Because they're heavier, steel wheels create more rolling resistance, which is made up of the forces that keep your vehicle from moving forward. Your engine uses more fuel with steel wheels, which is bad for the environment and your budget.

• Less agility.

Don't expect super sporty handling with your steel wheels. With these wheels, your vehicle's centre of gravity is lower, which affects acceleration and braking. Your suspension is also a bit more stressed with steel wheels.

Wheel-Buying Guide

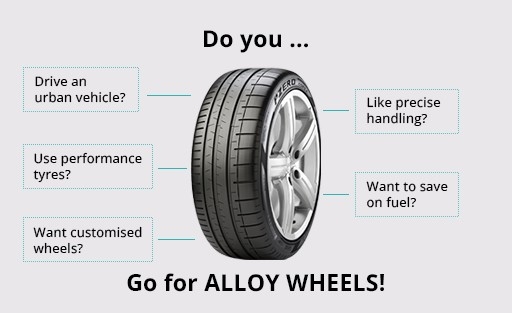

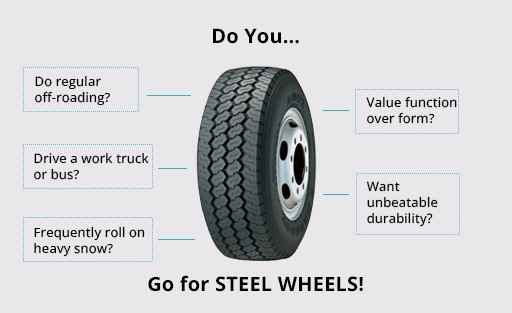

Here's an infographic to help you better decide between steel and alloy wheels.

Wheels at the Best Deals

Be it steel or alloy wheels, make sure your choice matches your vehicle and budget. Tyroola has many of the world's best wheel brands and, soon, tyre and wheel packages that will fulfil all your driving needs.

Shop at Tyroola now to get the best deals and promos for tyres and wheels!